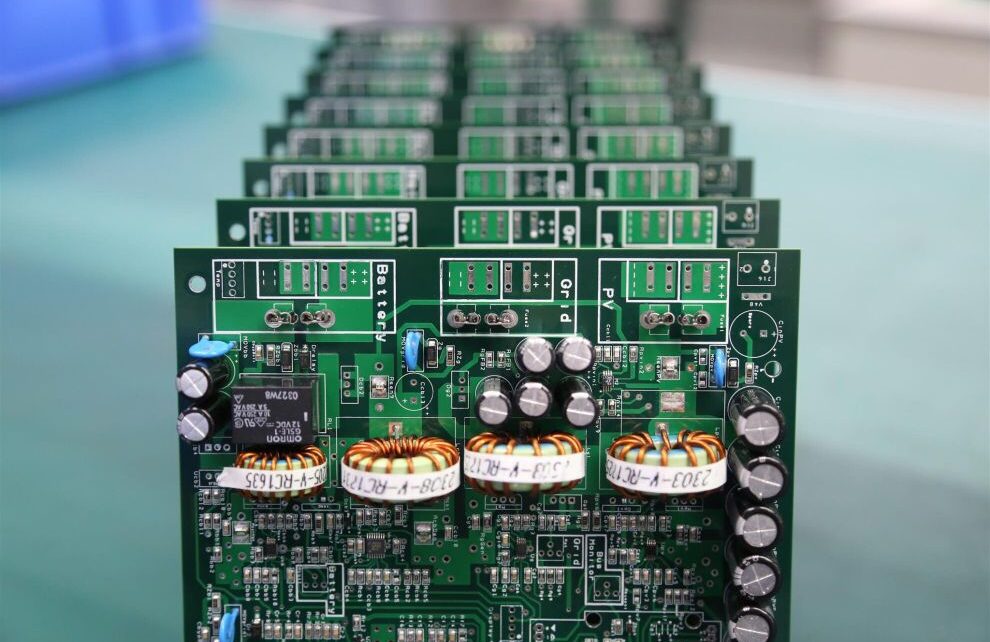

This Article aims to a question that how much does a custom PCB cost? The main purpose of PCBs is to enable the flow of electricity in electronic devices. The electric flow created by PCBs is effective and reliable. When it comes to the cost of custom PCBs, the answer relies on design and production. The cost rate of custom PCBs can have an impact on a person’s or company’s budget, Read more.

Let’s examine the expenses associated with cost of pcb board and talk about potential cost-cutting techniques.

Using this knowledge, you may decide which PCB manufacturing options are the most cheap for you. To read more about the making of custom PCB you should go through valuable sites.

But here you will get complete assistance on the cost of custom PCB. No matter whether you are an expert or a hobbyist you get some valuable information here.

So, Let’s begin discussion and understand the world of custom PCBs and explore the factors that determine their cost.

A Cost Guide for Custom PCB Manufacturing

A PCB might be small, but it is mighty. They have several factors that affect their costs in order to do their jobs efficiently and effectively.

PCB Layer’s Size and Numbers

Unlike simpler single-layer boards, high-tech electronic PCBs frequently include many layers. Due to the additional complexity, boards with components on both sides or many layers are more expensive.

The requirement for various components demands the use of layered layers. Larger boards are more expensive, not just because of their size but also because of the increased space needed for components. Larger boards and those with several layers require longer to produce, which contributes to the higher price.

Size of Board Holes

The size of the holes on a printed circuit board might affect the cost of production. Drilling correctly becomes more difficult when the holes are bigger or the board is small and tightly packed. These holes are required for connecting the board and sending signals between components.

Cost of Labor

Making PCBs is expensive because it requires skilled people and complex gear. Because labor costs influence the overall cost, it is vital that this job is performed by qualified employees. Paying a decent wage for best work upfront is cheap than having unskilled people construct subpar boards.

Board Size

Larger PCBs need more raw materials, longer production periods, and more processing. As a result, they are more costly. It is important to carefully analyze the board’s size while balancing usefulness and cost.

Testing and assurance of quality

PCBs must be thoroughly tested and quality controlled. For complex applications, extra testing may be required, raising the overall cost of the project.

Timeline

Urgent orders or projects with short deadlines may incur an extra price. We are compelled to speed up our production operations and handle rush orders on a priority basis. As a result onrush orders, which can dramatically raise our prices.

Placing and assembling

Assembly and component placement also have an impact on costs. SMT components are smaller and need more precise alignment. As a result, they need more labor and are therefore more expensive than their through-hole counterparts.

Additional requirements

To increase the performance and durability of a PCB, gold plating, impedance control, and specific coatings can all be employed. Furthermore, meeting other needs, like as RoHS compliance or industry norms, may affect the overall cost.

These characteristics provide value by ensuring higher conductivity, corrosion resistance, and adherence to important criteria.

While they are more expensive, they significantly improve PCB quality and dependability, making them attractive investments for critical applications in high-tech circuits.

As a result, while these modifications increase the initial cost, they result in a more robust and reliable PCB over time.

How to choose a PCB manufacturer

When choosing a PCB manufacturer, don’t only look at the pricing. It is critical to evaluate a variety of aspects.

First, look at their area of expertise and the quality of their items. For example, if you require PCBs for cellphones, be sure they specialize in this rather than, say, high-tech washing machine boards.

Once you’ve found a manufacturer who meets your criteria, determine whether they provide high-quality boards at a fair price.

To acquire an accurate price, provide precise information about your product. This contains information regarding the PCB’s functions as well as any particular needs.

Remember that focusing appropriateness and quality over cost guarantees that you acquire PCBs that precisely fulfill your requirements, resulting in a successful and dependable end product.

Conclusion

Several factors influence the price of a custom PCB, such as the board size, the complexity, and the quantity of the board.

PCB design and manufacturing are typically included in the cost. When choosing a vendor, consider the manufacturer’s expertise and experience, as this can affect the PCB’s cost and quality.

A comparison of PCB quotes from multiple reputable PCB manufacturers can help you make an informed decision. It will also ensure that you receive a high-quality, competitively priced custom PCB.