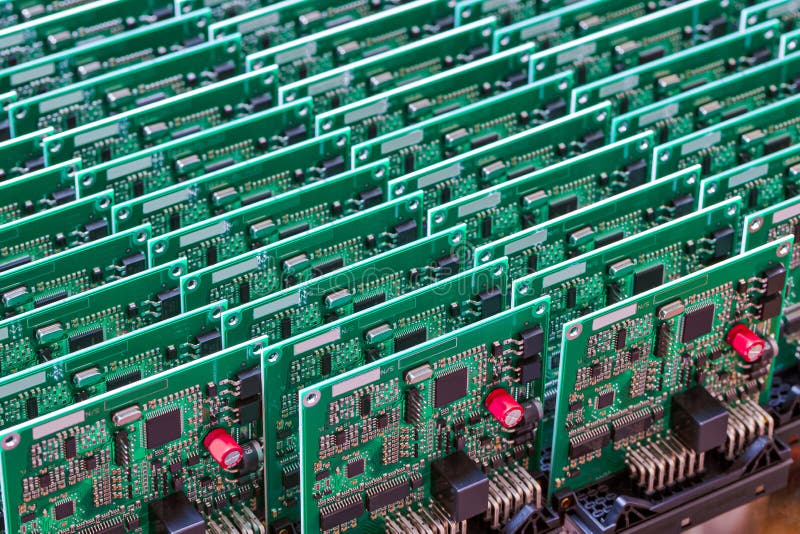

The PCB Assembly process is highly important in the electronics manufacturing industry, serving as the backbone of many technologies. As we look towards the future, certain advancements in PCBA are essential to propel technology forward. These enhancements are not just about refining current capabilities but are pivotal for unlocking new innovations and applications across various sectors.

Learn more about PCB assembly process.

Integration of Advanced Materials

The incorporation of advanced materials into PCBAs is fundamental. Materials with higher conductivity, improved thermal management, and enhanced durability can significantly boost performance. For instance, using graphene or advanced polymers could lead to lighter, more efficient, and more robust electronic devices.

Enhanced Manufacturing Precision

Precision in manufacturing is increasingly critical as devices become more complex and compact. Advancements in laser etching, 3D printing, and automated assembly lines promise to enhance the accuracy of PCBAs. This precision is essential for miniaturizing components and supporting the intricate designs of next-generation electronics.

Robust Design Software and Tools

The role of sophisticated design software and simulation tools cannot be overstated. As PCBA becomes more complex, the need for accurate design and testing tools grows. Software simulating electrical, thermal, and mechanical stresses in real time will be invaluable. This enables designers to identify potential issues early in development, saving time and resources.

Seamless Integration of AI and IoT

Artificial Intelligence and the Internet of Things, mostly known for their acronyms, AI and IoT respectively, are set to play a crucial role in the future of PCBA. AI can optimize manufacturing processes, improve quality control, and enhance product design. Meanwhile, integrating IoT capabilities into PCBAs will be fundamental for developing smart devices that are interconnected and capable of advanced functionalities.

Flexibility and Adaptability

As the need for flexible and wearable electronics rises, PCBAs that are adaptable, bendable, and stretchable will be key features needed to support these technologies. This flexibility will enable a new generation of wearable devices, from health monitors to smart textiles, pushing the boundaries of how and where technology can be used.

Sustainability and Environmental Consideration

Sustainability is becoming a pressing concern in all manufacturing processes, including PCBA. Features that promote environmental sustainability, such as recyclable materials, energy-efficient manufacturing processes, and designs that minimize waste, will be increasingly important. The electronics industry is moving towards a greener future, and PCBAs will play a significant role in this transition.

Enhanced Connectivity Features

As the world becomes more connected, PCB board manufacturers will need to create PCBAs that support a wider range of connectivity options. This includes not just Wi-Fi and Bluetooth but also newer standards like 5G and beyond. Enhanced connectivity features will enable faster data transfer rates, improved reliability, and broader coverage, essential for the next wave of connected devices.

Improved Power Management

Efficient power management is crucial for portable and wearable devices. Advances in PCBA design must include features that optimize power consumption, improve battery life, and support alternative energy sources like solar power. This will be particularly important for devices in remote locations or those that are part of IoT networks, where efficient power use is critical.

Ceramic PCB refers to a special process board in which copper foil is directly bonded to the surface of alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate (single-sided or double-sided) at high temperature. The ultra-thin composite substrate produced has excellent electrical insulation performance, high thermal conductivity, excellent brazing performance, and high adhesion strength.

Thanks for the clear explanation! Ceramic PCBs are definitely a great choice for high-heat and high-performance applications due to their excellent thermal and electrical properties.