A laser diode is a semiconductor device that emits coherent light through the process of stimulated emission. It operates similarly to a light-emitting diode (LED) but produces a focused, monochromatic, and coherent beam of light. The emitted light waves have the same wavelength, frequency, and phase.

The laser diode was invented by Theodore H. Maiman, an American physicist, and has since become an essential component in countless modern technologies. Today, laser diodes are widely used in fiber-optic communication systems, barcode readers, laser printers, CD/DVD drives, and optical scanners, where precise, high-intensity light is crucial.

What is a Laser Diode?

The term LASER stands for Light Amplification by Stimulated Emission of Radiation. A laser diode is a semiconductor-based PN junction device that converts electrical energy into coherent light energy through a process known as stimulated emission. It functions similarly to an LED, but the key difference lies in the mechanism of light generation and the nature of emitted light.

In an LED, light is emitted spontaneously as electrons and holes recombine. In a laser diode, on the other hand, an incident photon triggers the emission of additional photons with the same phase, frequency, and direction, resulting in a powerful and sharply focused beam of light.

The emitted radiation from a laser diode is typically coherent, monochromatic, and directional, making it ideal for high-speed optical communication and precision applications.

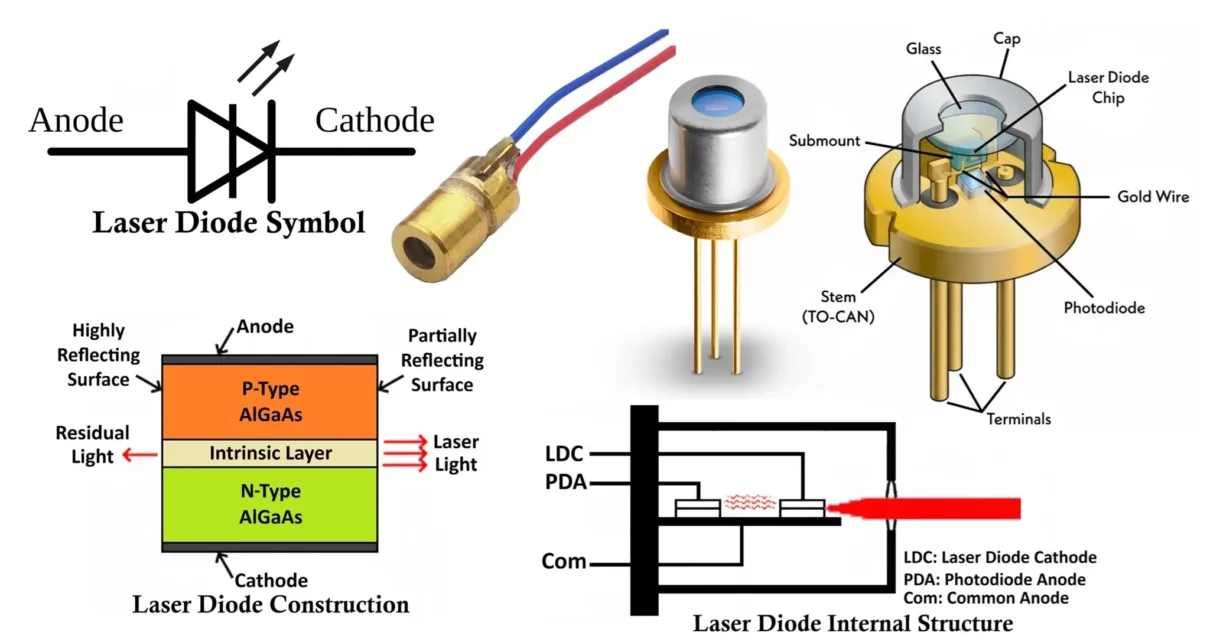

Symbol of Laser Diode

The circuit symbol of a laser diode closely resembles that of an LED, but with a key distinction:

It includes an extra vertical line to represent the optical feedback or resonant cavity that differentiates a laser diode from a simple LED.

- The triangle and bar represent the PN junction.

- The two arrows (→→) indicate coherent light emission.

- The vertical line signifies the optical cavity responsible for stimulated emission.

Three Terminal Laser Diode

A typical laser diode package usually consists of three terminals:

Most laser diodes actually house two semiconductor devices in a single package — the laser diode itself and a monitor photodiode for feedback control.

- The common terminal is connected to the positive supply.

- The LDC (Laser Diode Cathode) and PDA (Photodiode Anode) terminals are connected to the negative side, ensuring that the laser diode is forward biased and the photodiode is reverse biased.

To maintain stable light output, a transistor-based current driver circuit is used. The laser diode connects to the transistor driver, while the photodiode monitors a small portion of the emitted beam. This photodiode converts a fraction of the backward-traveling laser light into an electrical signal, which is sent as feedback to the current regulator. The regulator then adjusts the current through the transistor, ensuring the laser operates at the correct and stable intensity.

This feedback control mechanism prevents damage due to overcurrent and stabilizes the optical output, making the system reliable and safe for continuous operation.

Two-Terminal Laser Diodes

In some cases, laser diodes are designed with only two terminals (anode and cathode), omitting the built-in photodiode. In these devices, only the laser junction is present, and both optical output monitoring and current regulation must be handled externally.

Since there is no internal feedback mechanism, maintaining stable light output depends entirely on the precision of the current driver circuit. Any variation in temperature or drive current can significantly affect the laser’s output power and wavelength.

Two-terminal laser diodes are typically used in simpler or cost-sensitive applications where constant monitoring is not required, or where an external optical feedback system is implemented separately. However, they require more careful design consideration to avoid overdriving and to ensure consistent performance.

- Laser diodes without feedback photodiodes are common in laser pointers, barcode scanners, CD/DVD/Blu-ray players, laser toys and simple alignment tools.

- Laser diodes with feedback photodiodes are common in optical fiber transmitters, laser printers, LiDAR systems and optical sensors.

Construction of Laser Diode

A laser diode is primarily built using three semiconductor layers — a P-type layer, an N-type layer, and a thin intrinsic (I) layer — forming what is known as a PIN structure. This configuration allows for efficient light amplification and stable lasing action.

1. Material Composition

The semiconductor material commonly used in laser diodes is Gallium Arsenide (GaAs). To form the PN junction:

- The P-type region is created by adding trivalent impurities such as aluminum (Al) or zinc (Zn).

- The N-type region is formed using pentavalent impurities like selenium (Se) or tellurium (Te).

- Between these two regions lies a thin intrinsic (undoped) layer of pure GaAs, which acts as the active region where light generation occurs.

Because all three layers (P, I, and N) are made of the same semiconductor material (GaAs), this configuration is called a Homojunction Laser Diode.

2. Structural Arrangement

The intrinsic layer is sandwiched between the P-type and N-type layers. Metal contacts are attached to both the P and N regions to form the anode (+) and cathode (–) terminals, respectively.

When a forward voltage is applied across these terminals, electrons from the N-type region and holes from the P-type region move toward the intrinsic region. Here, they recombine to release energy in the form of photons (light particles). This intrinsic or active layer is the heart of the laser diode, where stimulated emission takes place.

3. Function of the Intrinsic Layer

The intrinsic layer increases the width of the PN junction, allowing more electrons and holes to meet and recombine. This larger active region enhances the photon generation rate, which leads to a stronger and more concentrated light beam.

The surfaces on either side of the active layer are coated with partially reflective materials:

- One side is fully reflective to bounce photons back into the cavity.

- The other side is partially reflective, allowing a controlled amount of light to escape as the laser output beam.

This design helps photons build up and reinforce each other inside the cavity, producing coherent and amplified light.

4. Focusing and Encapsulation

To further enhance the output beam:

- A miniature lens is placed at the emission point to focus the laser light into a sharp, narrow beam.

- The entire laser diode structure is enclosed within a metal casing that shields it from mechanical and environmental damage.

- A small aperture or opening in the casing allows the laser beam to exit in a single, well-defined direction.

This encapsulated design ensures optical precision, thermal stability, and protection from dust or moisture, thereby improving the performance and lifespan of the laser diode.

Working Principle of Laser Diode

The Laser Diode operates on the same basic principle as a Light Emitting Diode (LED) — the phenomenon of Electroluminescence, where a material emits photons (light) when an electric current passes through it. However, unlike LEDs, a laser diode produces coherent and monochromatic light, meaning the emitted photons are all in phase, have the same wavelength, and travel in the same direction.

1. Principle of Electroluminescence

When a laser diode is forward-biased, electrons from the N-type region gain enough energy to cross the PN junction and recombine with holes in the P-type region. During this recombination, the electrons release energy in the form of photons.

The process depends on the type of semiconductor material used. Only certain materials — such as Gallium Arsenide (GaAs), Gallium Arsenide Phosphide (GaAsP), and Aluminum Gallium Arsenide (AlGaAs) — can emit light efficiently because they possess a direct band gap.

Materials like silicon (Si) and germanium (Ge) have indirect band gaps, meaning they primarily release energy as heat instead of light, making them unsuitable for laser diodes.

2. Energy Band Theory

According to the energy band theory of solids, electrons occupy the valence band at low energy states. When these electrons absorb external energy (from a voltage source), they jump to a higher energy level called the conduction band, leaving behind vacant positions known as holes.

These excited electrons are unstable and naturally tend to return to their original, lower energy level (valence band). When they do so, the energy difference between the two bands (band gap energy) is released in the form of light photons.

3. Direct and Indirect Band Gap Materials

Direct Band Gap Semiconductors

In a direct band gap material, the conduction band minimum and the valence band maximum occur at the same momentum level (along the energy vs. momentum axis). This allows electrons to recombine directly with holes, releasing energy efficiently as light photons.

Examples include:

- Gallium Arsenide (GaAs)

- Aluminum Gallium Arsenide (AlGaAs)

- Gallium Arsenide Phosphide (GaAsP)

- Indium Gallium Nitride (InGaN)

- Zinc Selenide (ZnSe)

These materials are commonly used for manufacturing high-efficiency laser diodes.

Indirect Band Gap Semiconductors

In indirect band gap materials like Silicon (Si) and Germanium (Ge), the valence and conduction bands are misaligned. Hence, electron-hole recombination requires an additional energy exchange (via phonons), resulting in heat generation instead of light emission. This makes them unsuitable for laser construction.

4. Modes of Operation (Three Stages of Laser Generation)

The laser diode converts electrical energy into a coherent optical beam through three fundamental steps — Energy Absorption, Spontaneous Emission, and Stimulated Emission.

Step 1: Energy Absorption

When forward bias is applied across the PN junction:

- Electrons in the valence band absorb energy and jump into the conduction band, leaving behind holes.

- These electrons and holes coexist for a short time (known as recombination time) before recombining.

This is the first stage where the active region becomes filled with excited carriers ready to emit light.

Step 2: Spontaneous Emission

In this stage, electrons in the conduction band spontaneously fall back into the valence band to recombine with holes.

During this recombination, energy is released in the form of photons. However, these photons are emitted randomly — they differ in direction, wavelength, and phase.

This is exactly how a light-emitting diode (LED) works. However, in a laser diode, there is an additional step that transforms this random light into a coherent beam.

Step 3: Stimulated Emission

This is the defining feature of a laser diode.

- Inside the laser diode, the two opposite faces of the semiconductor crystal are polished and coated to act as partially reflecting mirrors.

- The photons generated during spontaneous emission bounce back and forth between these mirrors, forming an optical resonant cavity.

- As these photons travel through the active region, they collide with other excited electrons that are about to recombine.

- When struck by these photons, the excited electrons emit additional photons that are in phase, have the same frequency, and travel in the same direction as the incident photons.

This process, known as stimulated emission, results in amplification of light inside the cavity. Once the intensity reaches a certain level (called the threshold current), some of the amplified light escapes through the partially reflective mirror, forming a powerful, coherent laser beam.

Types of Laser Diode

Laser diodes are available in various designs and structural configurations, each optimized for specific applications such as communication, sensing, and optical storage. The main types of laser diodes are discussed below.

1. Double Heterostructure Laser Diode

The word “hetero” means different. In a Double Heterostructure Laser Diode, the active (intrinsic) layer is made from a different semiconductor material than the surrounding P-type and N-type layers.

This structure forms two junctions, one on each side of the active region — hence the name “double heterostructure.”

Structure:

- The middle layer (active region) has a narrow band gap.

- The outer P-type and N-type layers have wider band gaps.

- The active region is typically made of Gallium Arsenide (GaAs), while the cladding layers are made of Aluminum Gallium Arsenide (AlGaAs).

Advantages:

- The thin active layer confines both electrons and photons efficiently.

- This leads to strong optical gain and high output power.

- The laser beam produced is highly focused, intense, and stable.

Double heterostructure lasers are among the most widely used diode designs due to their low threshold current, high efficiency, and compact construction.

2. Quantum Well Laser Diode

A Quantum Well Laser Diode has an extremely thin active region, often only a few nanometers thick. The narrowness of this layer causes quantum confinement, meaning that the motion of charge carriers (electrons and holes) is restricted to a very small region.

This confinement leads to the formation of discrete energy levels known as quantum wells.

Working:

- The thin active region reduces the energy difference between the conduction and valence bands.

- As a result, electrons can recombine more efficiently with holes.

- The laser diode thus reaches the threshold current more easily and emits shorter-wavelength light compared to conventional lasers.

Advantages:

- Higher efficiency and lower threshold current.

- Improved temperature stability and faster modulation.

- Suitable for high-speed optical communication systems.

3. Separate Confinement Heterostructure (SCH) Laser Diode

In a Quantum Well Laser, the active region is very thin, which can make it difficult to confine photons effectively. To solve this, the Separate Confinement Heterostructure (SCH) laser diode introduces additional cladding layers with lower refractive indices around the active region.

These extra layers act as optical waveguides, trapping the light more efficiently within the cavity.

Working:

- The central quantum well remains the main light-emitting region.

- The surrounding cladding layers help guide and confine the optical field.

- This increases the optical gain due to multiple reflections of photons within the cavity.

Advantages:

- Enhanced optical confinement and higher efficiency.

- Better beam quality and lower optical losses.

- Ideal for precision and high-power applications.

4. Vertical Cavity Surface Emitting Laser (VCSEL)

The Vertical Cavity Surface Emitting Laser (VCSEL) differs fundamentally from conventional edge-emitting laser diodes.

In VCSELs, the optical cavity is oriented along the same axis as the current flow, and the laser beam is emitted vertically from the top surface of the chip rather than from its edge.

Structure and Working:

- The active region is placed between two Distributed Bragg Reflectors (DBRs) — highly reflective mirrors that form the resonant cavity.

- The laser light builds up between these mirrors and exits through the top surface as a circular, low-divergence beam.

Advantages:

- Easier testing and fabrication: Each device can be tested on the wafer before being separated, reducing production time and material waste.

- High reliability and low cost for mass production.

- Circular beam output, making it easy to couple with optical fibers.

- Widely used in data communication, optical sensors, and laser mice.

Characteristics of Laser Diode

Laser diodes possess several unique characteristics that distinguish them from ordinary light-emitting diodes (LEDs). These properties make them ideal for applications requiring precision, intensity, and coherence of light.

1. Monochromatic Light

A laser diode emits monochromatic light, meaning it produces light of a single wavelength or color.

This wavelength depends on the semiconductor material and the energy band gap used in the diode.

The emitted light is highly pure and concentrated, allowing the beam to be focused into a very small spot with minimal spectral spread.

2. Coherent Light

The light emitted by a laser diode is coherent, which means that all the emitted photons are in phase and have the same frequency.

This phase alignment allows the waves to constructively interfere, producing a highly amplified and intense beam.

This coherence is what gives the laser its distinct brightness and sharpness compared to ordinary light sources.

3. Directional (Well-Directed) Beam

Laser diodes emit light that is highly directional — the photons travel in a single, narrow beam rather than spreading out in all directions as in an LED.

The internal structure of the diode acts as a waveguide, channeling the photons toward one direction.

Additionally, an external focusing lens is often used to collimate and concentrate the light further into a precise, narrow beam.

PI Characteristics Curve of Laser Diode

The Power-Current (PI) characteristic curve illustrates the relationship between the optical output power and the input drive current of a laser diode.

- The x-axis represents the input current (I).

- The y-axis represents the optical output power (P).

Initially, when the current is below a certain limit known as the threshold current (Iₜₕ), the diode emits weak light due to spontaneous emission.

As the input current increases and exceeds the threshold, stimulated emission begins.

At this point, the optical output power rises exponentially, producing a high-intensity, coherent laser beam.

Key Points:

- Below the threshold → only weak spontaneous emission.

- Above the threshold → strong stimulated emission and rapid power increase.

- The slope of the curve above the threshold indicates the efficiency of the laser diode.

VI Characteristics of Laser Diode

The Voltage-Current (VI) characteristic of a laser diode represents the relationship between the forward voltage and the current passing through it.

Like a standard PN junction diode, the laser diode requires a minimum forward voltage to conduct — known as the junction or forward voltage (Vf).

However, this forward voltage is typically higher than that of a normal LED or silicon diode.

- Most laser diodes have a forward voltage of approximately 1.5V.

- Below this voltage, no significant current flows through the junction.

- Once the voltage exceeds this value, the current rises sharply due to conduction and photon generation.

Temperature Effect:

An increase in temperature reduces the forward voltage of the diode and may also increase the threshold current, affecting the overall stability and output efficiency of the laser diode. Therefore, thermal management is essential for reliable operation.

Advantages of Laser Diode

Laser diodes offer several key benefits that make them widely used in modern electronics, communication, and industrial applications:

- High Efficiency:

Laser diodes convert electrical energy into light very efficiently, providing strong output power with minimal energy loss. - Coherent and Monochromatic Light:

The emitted light has a single wavelength and is in phase, which allows for high-precision applications such as fiber-optic communication and holography. - Highly Directional Beam:

The narrow, well-collimated light can be focused onto a tiny spot, ideal for laser printing, optical reading, and precise measurements. - Fast Modulation Capability:

Laser diodes can be switched on and off very quickly, making them suitable for high-speed data transmission in optical communication systems. - Compact and Lightweight:

These devices are small in size, easy to integrate into circuits, and require minimal space, which is useful for portable devices. - Durable and Reliable:

With proper thermal management and current regulation, laser diodes offer long operational life and consistent performance.

Disadvantages of Laser Diode

Despite their advantages, laser diodes also have some limitations:

- Temperature Sensitivity:

Laser diode performance is highly affected by temperature. Excessive heat can reduce output power and increase threshold current. - Limited Lifespan Compared to LEDs:

Over time, prolonged use or overcurrent can degrade the active region, shortening the operational life. - Requires Precise Drive Circuitry:

A constant current source and feedback control are needed to prevent overcurrent, which can damage the diode. - Eye Hazard:

The intense coherent light can cause eye injury, so proper safety precautions are necessary when handling high-power laser diodes. - Narrow Wavelength Range:

Most laser diodes emit light at a fixed wavelength determined by the semiconductor material, which limits flexibility.

Applications of Laser Diode

Laser diodes are used in a wide variety of applications across multiple fields:

- Optical Communication Systems:

Used in fiber-optic networks for high-speed data transmission due to their coherent and monochromatic light. - CD, DVD, and Blu-ray Drives:

For reading and writing data on optical storage media. - Barcode Scanners:

In retail and logistics for fast and accurate scanning of products. - Laser Printers and Copiers:

Producing precise, high-resolution printing by scanning a laser beam across a photoreceptor. - Laser Pointers:

Compact and portable for educational and presentation purposes. - Medical Instruments:

Used in surgery, eye treatment, and diagnostics due to precise and focused beams. - LIDAR and Range-Finding Systems:

Employed in distance measurement, autonomous vehicles, and mapping. - Industrial Cutting and Welding:

High-power laser diodes are used for cutting, engraving, and welding in manufacturing. - Optical Sensors and Measurement:

For position sensing, alignment, and scientific instrumentation. - Military and Defense:

Used in targeting, range finding, and communication systems.

Summary

A laser diode is an advanced semiconductor device capable of generating coherent, monochromatic, and directional light. Its unique PIN or heterostructure design, combined with optical feedback, allows it to produce high-intensity beams for a wide variety of applications.

- Laser diode operates on the principle of stimulated emission, amplifying light within a resonant cavity.

- Laser diodes come in multiple types, such as Double Heterostructure, Quantum Well, SCH, and VCSEL, each optimized for specific applications.

- They exhibit unique characteristics, including monochromaticity, coherence, and directional emission.

- While highly efficient and precise, they require careful current control and thermal management to maintain performance and longevity.

In essence, laser diodes are indispensable in modern electronics, communication, medicine, and industry, providing reliable, high-speed, and high-precision light sources that continue to drive innovation worldwide.

Types of Diodes with Symbol, Definition, Working and Applications

Photodiode – Symbol, Construction, Working, Types and Applications

VI Characteristics of Zener Diode, Working and its Applications

Types of Transistors: Classification (BJT, JFET, MOSFET & IGBT)