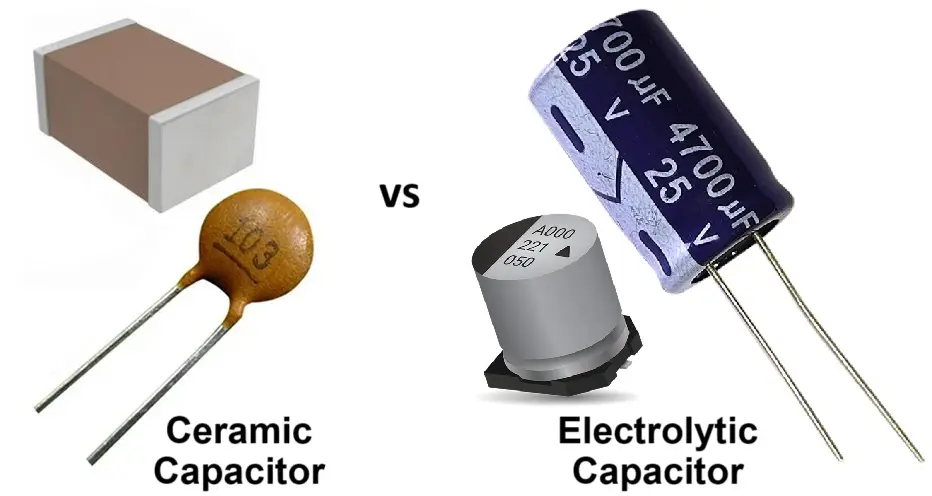

Introduction: In electronic circuit design or repair, selecting the right capacitor is critical to performance and reliability. Ceramic and electrolytic capacitors are two of the most commonly used capacitor types, each suited for distinct applications due to their differing structures and electrical characteristics.

Understanding their key differences – including capacitance range, frequency response, polarity requirements, and lifespan – can help engineers and hobbyists make the best choice for their projects. This article will provide a detailed comparison of these two capacitors, highlighting their differences and respective application scenarios.

1. What Is an Electrolytic Capacitor?

Electrolytic capacitors utilize an electrolyte – a conductive liquid or gel rich in ions – to achieve high capacitance in compact sizes. These polarized components require strict voltage polarity, with the positive terminal always maintained at a higher potential than the negative.

They are categorized into wet electrolyte (traditional liquid-based) and solid polymer (modern, stable) types, commonly constructed from aluminum or tantalum. Widely deployed in computer motherboards, power supplies, and household appliances, electrolytic capacitors excel in smoothing voltage fluctuations and energy storage.

Electrolytic capacitors can be classified by electrolyte type – wet (liquid), solid polymer, or hybrid; by electrode material – aluminum, tantalum, or niobium; and by construction style – radial, axial, or surface-mount (SMD). Specialized variants include low-ESR types for high-frequency circuits, high-temperature models for harsh environments, and long-life designs for industrial or mission-critical applications.

2. What Is a Ceramic Capacitor?

Ceramic capacitors are a fundamental type of passive electronic component constructed using ceramic material as the dielectric, with silver or other metal electrodes applied to each layer of the substrate. They are typically fired at high temperatures to sinter the ceramic and electrode layers into a solid structure. Most ceramic capacitors are produced in compact, surface-mount (SMD) chip configurations, although tubular and disc-shaped variants are also available for specific applications.

Offering exceptional versatility, ceramic capacitors are categorized based on key operational parameters: voltage ratings span high-voltage (for power systems), medium-voltage (general-purpose circuits), and low-voltage (miniaturized electronics) classes, while their temperature coefficients and dielectric properties further classify them into negative temperature coefficient (NTC), positive temperature coefficient (PTC), zero temperature coefficient (stable for precision timing), high dielectric constant (enabling compact high-capacitance designs), and low dielectric constant (optimized for high-frequency signal integrity) types.

This broad classification underscores their adaptability across industries from consumer electronics and telecommunications to automotive systems and aerospace technology—where their reliability, miniaturization potential, and stable performance under varying environmental conditions make them indispensable.

3. Electrolytic Capacitor vs Ceramic Capacitor

| Characteristic | Electrolytic Capacitor | Ceramic Capacitor |

|---|---|---|

| Capacitance range | Higher (µF to thousands of µF) | Lower (pF to a few µF) |

| Polarization | Polarized, must be connected with correct polarity | Non-polarized, can be connected either way |

| Frequency response | Poor for high frequency, better for low frequency filtering | Excellent for high-frequency applications |

| Temperature stability | Moderate, some degradation over time and heat | Very stable (Class I types), but Class II/III may vary with temp |

| Price | Generally lower | Generally higher (for high-quality types) |

| ESR | Higher than ceramic | Very low ESR |

| Rated voltage | Commonly up to ~500V (special types higher) | Can exceed 1 kV in certain designs |

| Current capacity | Can handle large ripple currents (depending on type) | Generally handles less ripple current but great for fast pulses |

4. Applications of Electrolytic and Ceramic Capacitors

4.1 Electrolytic Capacitors

- Power Supply Filtering – Smooth DC voltage by filtering ripple from rectified AC.

- Energy Storage – Store energy for bursts of power in circuits such as camera flashes.

- Decoupling – Suppress voltage fluctuations in power lines feeding ICs or modules.

- Timing Circuits – In RC timing configurations where large capacitance is required.

- Audio Coupling/Bypass – Block DC while allowing audio-frequency AC signals to pass.

- Motor Start/Run Circuits – In certain single-phase AC motor applications (special electrolytic designs).

- Low-Frequency Filtering – In speaker crossovers or low-pass filters where large capacitance is beneficial.

4.2 Ceramic Capacitors

- High-Frequency Filtering – In RF circuits, oscillators, and bypass networks.

- Decoupling/Bypass – Provide a short path for high-frequency noise to ground in digital and analog circuits.

- Coupling in Signal Paths – Pass AC signals between amplifier stages without affecting DC bias.

- Resonant Circuits – In LC tank circuits for tuners and oscillators.

- Snubber Circuits – Suppress voltage spikes in switching power supplies and motor drivers.

- Precision Timing – In oscillators and timing circuits where stability over temperature is important (using Class I ceramics like NP0/C0G).

- EMI Suppression – In input filters for compliance with electromagnetic interference standards.

5. Other capacitor types

5.1. Film Capacitors

Film capacitors use ultra-thin plastic or polymer films as dielectrics, typically polypropylene (PP), polyester (PET), or polyphenylene sulfide (PPS). These films are manufactured for uniform thickness and minimal defects, and may be metallized (for self-healing properties) or left non-metallized for higher current handling. Electrodes are applied as metal foils or sprayed metallic layers, and the assembly is encapsulated in epoxy resin or ceramic for protection.

They offer low distortion, high stability, and excellent frequency response, making them ideal for high-frequency circuits, high-voltage systems, and precision analog equipment. Applications include RF filters, power inverters, automotive electronics, renewable energy systems, and industrial automation.

5.2. Mica Capacitors

Mica capacitors are made by layering mica sheets coated with metal on both sides, then encapsulating them in epoxy resin. They are valued for stability, reliability, and low loss, making them suitable for high-frequency use. Silver mica variants are common for small capacitance values (a few pF to a few nF) in precision circuits.

5.3. Tantalum Capacitors

Tantalum capacitors are electrolytic capacitors using tantalum as the anode and tantalum pentoxide as the dielectric. They provide high capacitance in small sizes, are polarized, and must be connected correctly to avoid damage. Known for low ESR and stable capacitance over temperature, they are used in power supply circuits, decoupling, and high-frequency applications. They are more expensive than aluminum electrolytics and sensitive to voltage spikes.

5.4. Aluminum Capacitors

Aluminum electrolytic capacitors use aluminum as the anode and aluminum oxide as the dielectric. They offer high capacitance at low cost, are polarized, and are available in radial, axial, and surface-mount forms. Common in power supplies, audio equipment, and general electronics, they are used for energy storage, filtering, and decoupling. They generally have higher ESR than tantalum types but provide good performance for many applications.

5.5. Supercapacitors

Supercapacitors (ultracapacitors or EDLCs) store energy via electrostatic charge separation rather than chemical reactions, enabling rapid charge/discharge cycles. They have very high capacitance values (farads to thousands of farads) but lower energy density than batteries. Construction includes two electrodes (often activated carbon) separated by an electrolyte and porous separator. They are used in energy storage systems, regenerative braking, backup power, and voltage smoothing. Their long cycle life and high power capability make them ideal for quick energy delivery needs.

5.6. Paper Capacitors

Paper capacitors use paper as the dielectric, impregnated with oil or wax to improve properties. Metal electrodes are applied to the paper layers, and the unit is encased for protection. Known for high voltage ratings and stability, they are used in power electronics, audio systems, and high-frequency circuits. Due to newer, more compact technologies, they are less common today.

5.7. Variable Capacitors

Variable capacitors allow manual or electronic adjustment of capacitance by changing the overlap or spacing between fixed and movable plates. They are mainly used in tuning circuits for RF applications where precise frequency control is required.

5.8. Trimmer Capacitors

Trimmer capacitors are small adjustable capacitors, typically with a ceramic or plastic body and a movable plate adjusted via screwdriver. They are used for fine-tuning in RF circuits, oscillators, and tuning systems.

5.9. Non-polarized Capacitors

Non-polarized capacitors can be connected in either direction and are suitable for AC applications. They come in various types, including ceramic, film, and tantalum, and are used in audio circuits, signal coupling, and decoupling where polarity is not fixed.

Conclusion:

In summary, ceramic capacitors and electrolytic capacitors serve distinct roles in electronic circuits, each with unique advantages and limitations. Ceramic capacitors excel in high-frequency applications, low ESR, and non-polarity, making them ideal for decoupling and filtering in digital circuits. In contrast, electrolytic capacitors are preferred for their high capacitance in power supply applications, despite their polarization and lower frequency response. Understanding these differences allows engineers to select the most suitable capacitor type for their specific needs, ensuring optimal performance and reliability in electronic designs.

FAQs

-

What is the difference between a ceramic capacitor and a capacitor?

“Capacitor” is a general term for all capacitive components, while “ceramic capacitor” specifically refers to those using ceramic as the dielectric material. Ceramic capacitors are a type of capacitor suitable for high-frequency, small-signal applications, while other capacitors are designed for different requirements.

-

What is the difference between a ceramic capacitor and an electrolytic capacitor?

They use ceramic as dielectric material, while electrolytic capacitors use an electrolyte solution. Ceramic capacitors are non-polarized, have low ESR, and are suitable for high-frequency applications.

In contrast, electrolytic capacitors are polarized, have higher capacitance values, and are typically used in low-frequency applications. Ceramic capacitors are more stable over temperature and voltage variations, while electrolytic capacitors can be larger and have a shorter lifespan in high-temperature environments.

-

Should I use a ceramic or electrolytic capacitor?

It depends on your requirements. If you need a small size, high-frequency performance, or high stability in temperature and voltage, choose a ceramic capacitor. If you need a large capacitance or for low-frequency circuits, use an electrolytic capacitor. Note that electrolytic capacitors have a shorter lifespan in high-temperature, high-frequency environments, so they should be avoided in such cases.

-

Why use ceramic capacitors?

Ceramic capacitors are preferred for their small size, low cost, excellent high-frequency performance, and high reliability. They feature low ESR (equivalent series resistance) and voltage stability, making them suitable for decoupling, filtering, and bypass applications in high-speed digital circuits (such as computers and mobile phones). Unlike electrolytic capacitors, ceramic capacitors are non-polarized, resistant to aging or leakage, and have a longer lifespan.

-

Can electrolytic capacitors be replaced with ceramic capacitors?

In some cases, but with limitations. Ceramic capacitors offer advantages such as small size, non-polarity, and excellent high-frequency performance. However, their capacitance (especially >100μF) and voltage rating are typically lower than those of electrolytic capacitors, and they may exhibit capacitance drop under DC bias and piezoelectric noise.

In low-frequency filtering or high-capacity applications (such as power decoupling), electrolytic capacitors remain irreplaceable. Before replacement, evaluate the capacitance, voltage rating, ESR, and circuit requirements.

Recommended Reading: what is a thermistor sensor?

Types of Capacitors with Symbol, Classification and Applications

Difference Between Coupling, Decoupling, and Bypass Capacitors

Types of Resistors with Symbol, Classification and Applications