Let’s understand the SMPS Block Diagram working. A Switch Mode Power Supply is an electronic power supply that incorporates a switching regulator to convert electrical power efficiently. Unlike linear power supplies, which convert excess energy into heat, SMPS circuit uses a switching element that rapidly turns on and off to regulate the output voltage and current.

Definition of SMPS:

Switch Mode Power Supply (SMPS): A power supply that uses a high frequency switching regulator to convert electrical power efficiently, typically from AC to DC, DC to DC, or DC to AC and AC to AC. The main components are a rectifier, filter, inverter, transformer, and feedback control.

SMPS Block Diagram – Working:

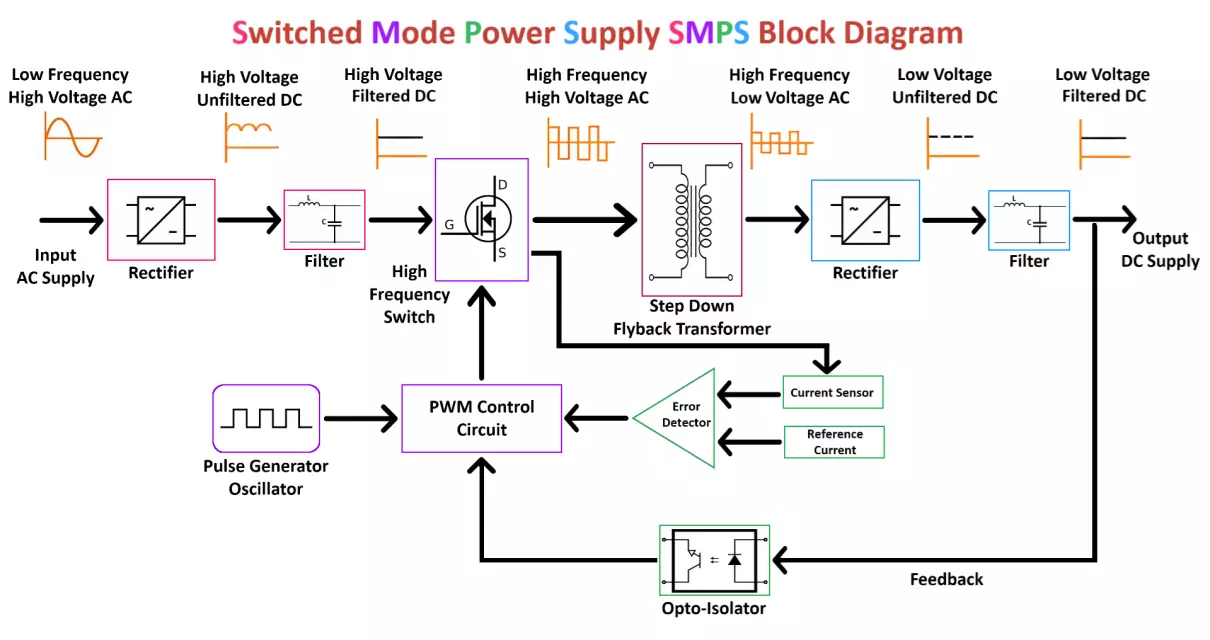

Switch Mode Power Supply (SMPS) is an efficient power supply that converts electrical power using switching devices that turn on and off at high frequencies and energy storage components like inductors or capacitors to supply power when the switching device is in its non-conduction state. The SMPS Block Diagram working can be divided into several stages:

1.) Input Stage:

- AC Input: The SMPS circuit receives AC input from the mains supply.

- Rectification and Filtering: The AC voltage is rectified using a bridge rectifier to convert it into a pulsating DC voltage. This DC voltage is then filtered using capacitors to produce a relatively smooth DC voltage.

2.) High-Frequency Switching:

- Switching Transistor: A high-frequency switching transistor (like a MOSFET or IGBT) is used to chop the DC voltage into a high-frequency AC signal. The switching frequency can range from 20 kHz to several MHz.

- PWM Control: The switching transistor is controlled by a Pulse Width Modulation (PWM) controller. The duty cycle of the PWM signal determines the output voltage.

Switch Mode Power Supply SMPS Block Diagram:

3.) Transformer Stage:

- High-Frequency Transformer: The high-frequency AC signal is fed into a high-frequency transformer. This transformer steps up or steps down the voltage to the desired level. The high-frequency transformers differ significantly from traditional 50/60 Hz transformers. Here are the key points:

- High-Frequency Operation: These transformers work at 20 kHz to several MHz, allowing for smaller and lighter designs.

- Ferrite Cores: They use ferrite cores to reduce eddy current losses at high frequencies.

- Compact Size: Higher frequencies enable the use of smaller, lighter transformers.

- Efficient Design: They minimize losses due to hysteresis and eddy currents, improving efficiency.

- Custom Windings: They have multiple windings for primary, secondary, feedback, and auxiliary power, tailored to specific voltage and current needs.

4.) Output Stage:

- Rectification: The high-frequency AC voltage from the transformer’s secondary winding is rectified using diodes (typically Schottky diodes for their fast-switching speed).

- Filtering: The rectified voltage is filtered using inductors and capacitors to smooth it out and provide a stable DC output.

5.) Feedback Mechanism:

Feedback control in an SMPS ensures that the output voltage remains stable despite changes in load or input voltage. It typically involves:

- Voltage Feedback: A portion of the output voltage is fed back to the PWM controller through an error amplifier. This feedback loop adjusts the PWM duty cycle to regulate the output voltage and maintain it within the desired range.

- Isolation: Optocouplers are often used in the feedback loop to maintain electrical isolation between the high-voltage primary side and the low-voltage secondary side.

- Error Amplifier: Compares output voltage to a reference voltage.

- Compensation Network: Stabilizes the feedback loop.

- Pulse Width Modulator (PWM): Adjusts the duty cycle of the switch to maintain the desired output voltage.

This is the working of SMPS block diagram let’s see its classification.

Types of SMPS:

By type of input and output current,

- AC-DC Converter: Converts AC mains voltage to a regulated DC output.

- DC-DC Converter: Converts a DC input voltage to a different DC output voltage.

- DC-AC Inverter: Converts DC input to an AC output.

- AC-AC Inverter: Converts AC input to another AC output voltage.

Types of SMPS Topologies:

Non-Isolated SMPS:

Direct connection between input and output without isolation.

- Buck Converter: Steps down the input voltage to a lower output voltage.

- Boost Converter: Steps up the input voltage to a higher output voltage.

- Buck-Boost Converter: Can step up or step down the input voltage.

Isolated SMPS:

Includes a transformer for isolation between input and output.

- Flyback Converter: Simplest and most common, used for low to medium power applications.

- Forward Converter: Used for higher power levels than flyback, with better efficiency.

- Push-Pull Converter: Used for medium to high power applications with balanced drive.

- Half-Bridge Converter: Suitable for higher power levels, offering a good balance of efficiency and complexity.

- Full-Bridge Converter: Used for very high-power applications, offering the highest efficiency and power handling.

Advantages of Switch Mode Power Supplies (SMPS):

- High Efficiency: SMPS are highly efficient (up to 90% or higher) because they minimize power loss by switching on and off rapidly and using high-frequency transformers.

- Compact Size and Lightweight: The use of high-frequency operation allows for smaller and lighter transformers and other components, making the overall unit more compact and easier to integrate into various applications.

- Wide Input Voltage Range: SMPS can handle a wide range of input voltages, making them suitable for use in different regions with varying electrical standards.

- Stable Output: SMPS provide stable and regulated output voltage even with variations in input voltage and load conditions, thanks to feedback mechanisms.

- Reduced Heat Generation: Higher efficiency translates to less heat generation, which reduces cooling requirements and enhances reliability.

- Versatility: They can provide multiple output voltages from a single input voltage, making them versatile for various applications.

- Better Power Factor: Many SMPS designs include power factor correction (PFC) circuits, improving the power factor and reducing the reactive power in the system.

Disadvantages of Switch Mode Power Supplies (SMPS):

- Complex Design: SMPS are more complex than linear power supplies, requiring more components and sophisticated design techniques.

- Electromagnetic Interference (EMI): The high-frequency switching can generate electromagnetic interference, which may require additional filtering and shielding to mitigate.

- Noise: SMPS can introduce high-frequency noise into the circuit, which can affect sensitive electronics and require additional filtering.

- Transient Response: Rapid changes in load can sometimes cause stability issues or slower transient response compared to linear power supplies.

- Cost: The complexity and additional components can make SMPS more expensive to design and manufacture than simpler linear power supplies.

- Component Stress: High-frequency operation can stress components, requiring high-quality parts.

- Maintenance and Repair: The complexity of SMPS can make them more difficult to troubleshoot, repair, and maintain compared to linear power supplies.

Applications of Switch Mode Power Supply SMPS:

Switch Mode Power Supplies (SMPS) are versatile and widely used across various applications due to their high efficiency, compact size, and reliability. Here are some key applications of SMPS:

1. Consumer Electronics

- Computers and Laptops: SMPS units are integral in powering desktops, laptops, and peripherals by providing stable and efficient power conversion.

- Televisions and Audio Equipment: Modern TVs, home theaters, and audio systems use SMPS for their power needs.

- Mobile Phone Chargers: Almost all mobile phone chargers use SMPS technology to convert AC mains to the required DC voltage.

2. Industrial Applications

- Automation Systems: SMPS is used to power PLCs, sensors, and other control systems in industrial automation.

- Motor Drives: Variable frequency drives (VFDs) and servo drives for controlling motors rely on SMPS for efficient power management.

- Industrial Equipment: Various industrial machines and tools, including welding equipment and CNC machines, utilize SMPS.

3. Telecommunications

- Base Stations: Telecom base stations and network infrastructure use SMPS for stable and reliable power.

- Networking Equipment: Routers, switches, and other networking devices are powered by SMPS.

4. Medical Equipment

- Diagnostic Machines: MRI machines, X-ray machines, and CT scanners require stable and reliable power provided by SMPS.

- Patient Monitoring Systems: Devices like ECG monitors, ventilators, and other patient care equipment use SMPS for consistent operation.

5. Automotive

- Electric and Hybrid Vehicles: SMPS units are used in battery management systems, onboard chargers, and other electronic control units.

- Infotainment Systems: Car audio systems, navigation units, and other in-car electronics use SMPS.

6. Aerospace and Defense

- Aircraft Systems: Avionics, communication systems, and control systems in aircraft rely on SMPS for efficient power conversion.

- Military Equipment: Various military electronics, including radar systems and communication equipment, use SMPS.

7. Renewable Energy

- Solar Inverters: SMPS technology is used in solar inverters to convert DC from solar panels to AC for home or grid use.

- Wind Turbine Control Systems: Power electronics in wind turbines utilize SMPS for efficient power management.

8. Portable Devices

- Battery Chargers: Chargers for portable devices, including cameras, power tools, and drones, use SMPS.

- Portable Power Supplies: Portable generators and power banks employ SMPS for efficient power conversion and management.

9. Lighting

- LED Drivers: SMPS units are used in LED lighting systems to provide the necessary current and voltage regulation.

- HID Lighting: High-intensity discharge lamps in street lighting and industrial lighting use SMPS for their power needs.

10. Embedded Systems

- Microcontroller-Based Systems: Various embedded systems, including IoT devices, sensors, and controllers, use SMPS for efficient power supply.

By understanding these key aspects, you can better appreciate the versatility and efficiency of SMPS in modern electronic devices.

Conclusion:

The SMPS efficiently converts electrical power through high-frequency switching, providing a stable and regulated output voltage. Its design and operation make it suitable for a wide range of applications, from consumer electronics and automotive systems to specialized industrial and medical equipment, by offering improved efficiency, reduced size, and weight compared to traditional linear power supplies. They are indispensable in modern electronic systems.

Working conditions could also have been added to this.

I have already added it, what else you want?

Please, I am just a notive that wants to be like you sir.

Very helpful and easy to understand. Thanks!