Capacitors are essential passive components used to store and release electrical energy. Among the many types, polarized capacitors hold a special place in electronics because they offer very high capacitance values in a small size something non-polarized capacitors cannot achieve.

Polarized capacitors are widely used in DC power supplies, filters, audio circuits, SMPS, motor controllers, and energy storage systems. However, they come with a critical requirement:

Polarized capacitors MUST be connected with correct polarity.

Incorrect polarity can cause leakage, permanent damage, overheating, or explosion.

This article covers the symbol, construction, working principle, detailed types (Aluminum, Tantalum, Niobium, Supercapacitors), advantages, disadvantages, failure modes, and applications of polarized capacitors in depth.

Related Articles:

- Types of Capacitors with Symbol, Classification and Applications

- Non-Polarized Capacitors – Symbol, Types, Working & Applications

- Difference Between Coupling, Decoupling, and Bypass Capacitors

- Ceramic vs Electrolytic Capacitor: Key Differences and Applications

What is a Polarized Capacitor?

A polarized capacitor is a capacitor that has a positive terminal (anode) and a negative terminal (cathode). It can only be used with DC voltage applied in the correct direction.

If the polarity is reversed:

- The dielectric layer breaks down

- Large leakage current flows

- Internal heating occurs

- The capacitor may vent, burst, or explode

This polarity restriction comes from how the dielectric is formed through an electrochemical oxidation process – a process that only works in one direction.

Polarized Capacitor Symbol

- Straight line = positive plate

- Curved plate = negative plate

- (+) indicates the positive terminal

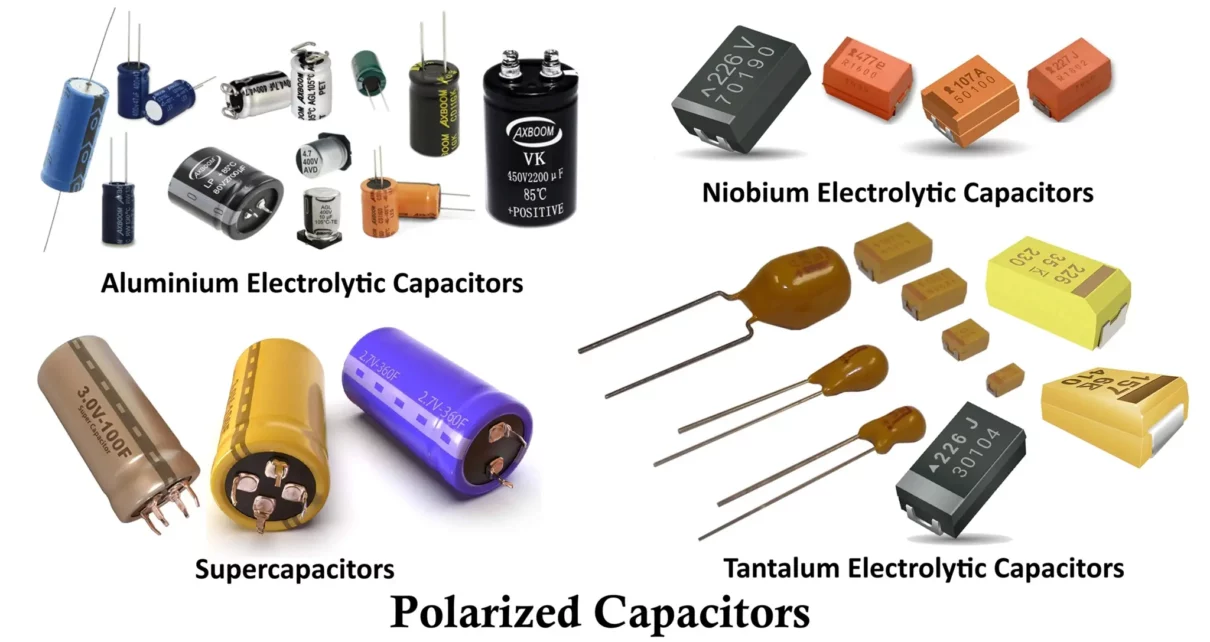

Types of Polarized Capacitors

We now describe each type in long and detailed form, combining your entire provided content with corrections and enhancements.

Aluminum Electrolytic Capacitors

These are the most widely used high-capacitance capacitors.

Characteristics

- Capacitance: µF → several Farads

- Voltage: 6.3V → 600V+

- Temperature: –40°C to +125°C

- Tolerance: ±10% to ±20%

- Polarity: Strictly polarized

- ESR: Higher than ceramic/film, but improved in polymer versions

Types of Aluminum Electrolytic Capacitors

1. Standard Aluminum Electrolytic

- Low cost

- Used in rectifier filters

- Moderate ESR

2. Low-ESR Aluminum (SMPS Grade)

- Designed for high-frequency ripple

- Used in switching regulators

- Improved lifetime and ripple handling

3. Polymer Electrolytic (Solid Polymer)

- Uses a conductive polymer instead of liquid electrolyte

- Very low ESR

- High ripple current capability

- Does not dry out like wet electrolytics

- Ideal for:

- SMPS

- Motherboards

- Graphics cards

- High-frequency power rails

Advantages

- High capacitance at low cost

- Good ripple handling

- Mature technology

- Widely available

- High voltage options

Limitations

- Shorter lifespan (electrolyte dries out)

- High ESR in standard versions

- Poor high-frequency performance

- Cannot handle reverse polarity

- Large size compared to ceramics

Applications

- SMPS input/output filters

- DC-Link capacitors

- Audio amplifier smoothing

- Motor driver power filtering

- Camera flash circuits

- Rectifier smoothing

Tantalum Electrolytic Capacitors

Tantalum capacitors offer better stability, longer lifespan, and lower ESR compared to aluminum types.

Characteristics

- Capacitance: 0.1 µF → 1000 µF

- Voltage: 2V → 50V

- Temperature: –55°C to +125°C

- Low ESR

- Stable capacitance over temperature

- Very low leakage current

- Extremely polarity-sensitive

Types of Tantalum Capacitors

1. MnO₂ Tantalum Capacitors

- Traditional type

- Good stability

- Moderate ESR

- Used in consumer electronics and general circuits

2. Polymer Tantalum Capacitors

- Very low ESR

- High ripple current

- Better reliability

- Preferred in:

- FPGA power rails

- CPU VRMs

- SSDs

- Telecom SMPS

Advantages

- High capacitance density

- Very stable characteristics

- Very low ESR

- Long life; no drying

- Compact size

Limitations

- Expensive

- Sensitive to overvoltage (may short-circuit)

- Low voltage ratings

- Must observe polarity strictly

Applications

- Power rail decoupling

- DC-DC converter filtering

- Medical electronics

- Aerospace electronics

- Smartphones and portable devices

- SSD voltage smoothing

Niobium Electrolytic Capacitors

Niobium capacitors were developed as a safer alternative to tantalum.

Characteristics

- Capacitance: 0.47 µF → 100 µF

- Voltage: 2.5V → 8V

- Temperature: –55°C to +125°C

- Lower leakage current than aluminum

- Safer failure mode than tantalum

- Moderate ESR

Types

1. Niobium Oxide (NbO₂) Capacitors

- Very safe

- Stable over time

- Excellent for low-power circuits

2. Niobium Polymer Capacitors

- Lower ESR

- Used in high-speed power rails

Advantages

- Safer than tantalum

- Good stability

- Low leakage

- More abundant material than tantalum

- Good thermal stability

Limitations

- Lower capacitance density

- Lower voltage ratings

- Not as low ESR as polymer tantalum

Applications

- SMPS decoupling

- Consumer electronics

- Automotive electronics

- Battery-powered low-leakage circuits

Supercapacitors (Ultracapacitors)

Although sometimes included under “polarized”, supercapacitors behave differently.

Technically, they are not true polarized electrolytics, but they must still be used with correct polarity because their construction is asymmetric.

Characteristics

- Capacitance: 0.1F → 5000F+

- Voltage: 2.7V → 3.8V per cell

- 1,000,000+ cycles

- Very fast charge/discharge

- Low ESR

Types

1. EDLC (Double Layer Supercapacitors)

- Most common type

- Used for energy storage and backup power

2. Pseudocapacitors

- Store energy using fast redox reactions

- Higher energy than EDLC

3. Hybrid Supercapacitors

- Combine EDLC + battery technologies

- Used in EVs

Advantages

- Ultra-high capacitance

- Extremely long cycle life

- Very fast charging

- High power delivery

Limitations

- Low voltage rating

- Higher self-discharge

- Lower energy density vs batteries

Applications

- Regenerative braking

- UPS backup

- Solar and wind energy smoothing

- Power surges in SMPS

- IoT memory retention

Construction of Polarized Capacitors

While there are several types, all polarized capacitors share a similar concept:

- A metal anode is oxidized to form a very thin dielectric layer (oxide film)

- The cathode is formed by a liquid or solid electrolyte

- The anode + dielectric + electrolyte form the complete capacitor

A thinner dielectric = higher capacitance, which is why these capacitors achieve high values.

Let’s examine the construction for major types.

Construction of Aluminum Electrolytic Capacitors

These are the most common polarized capacitors.

Main Components

- Anode Foil (Etched Aluminum)

- Chemically etched to drastically increase surface area

- Anodized to grow a thin layer of Al₂O₃ Aluminum Oxide dielectric

- Cathode Foil

- Aluminum foil contacting the electrolyte

- Electrolyte

- Liquid or solid

- Acts as the real conductive cathode

- Separator Paper

- Holds electrolyte in place

- Insulates anode and cathode foils

- Wound Foil Structure

- Foils are rolled into a cylindrical stack

- Aluminum Can + Rubber Seal

- Seals electrolyte

- Provides mechanical protection

The dielectric Aluminum oxide is extremely thin (tens of nanometers), allowing high capacitance.

Construction of Tantalum Capacitors

Tantalum capacitors use tantalum metal powder pressed into a porous pellet.

Construction Steps

- Sintered Tantalum Pellet

- Creates an extremely large internal surface area

- Dielectric Formation

- The pellet is anodized to form Ta₂O₅ oxide, which is a superior dielectric

- Cathode Material

Two major types:- MnO₂ solid electrolyte

- Conductive polymer electrolyte (modern, low ESR)

- Carbon + Silver Layers

- Provide conduction from electrolyte to external lead

- Epoxy Encapsulation

- High stability

- Moisture-resistant

Why Tantalum Has High Capacitance Density?

The porous structure gives huge surface area, and Ta₂O₅ dielectric has a high dielectric constant.

Construction of Niobium Capacitors

Niobium capacitors are similar to tantalum but use niobium or niobium oxide pellets. It offers safer failure mode, lower ignition risk and lower leakage current than aluminum electrolytics.

Construction of Supercapacitors

Supercapacitors differ from electrolytics:

- They use carbon electrodes

- Charge is stored by Electrochemical Double Layer (EDLC)

- No oxide dielectric

- Not truly “polarized” in chemical sense, but used with correct polarity

Working of Polarized Capacitors

Polarized capacitors work based on the formation of an electric field across a dielectric oxide film.

- A DC voltage is applied across the capacitor.

- The oxide dielectric on the anode prevents electron flow.

- Charges accumulate:

- Positive charge on anode

- Negative charge on electrolyte (cathode)

- Energy is stored in the electric field.

Why Polarity Matters?

If reverse voltage is applied:

- The dielectric oxide starts dissolving

- Leakage current increases

- Heat is generated

- Electrolyte may vaporize

- The capacitor may vent or explode

Capacitance Formula

C = εA/d

- ε → dielectric constant

- A → surface area of anode

- d → oxide layer thickness

Aluminum and tantalum allow extremely thin oxide layers, giving high capacitance.

Common Failure in Polar Capacitors

Common failure reasons include:

- Leakage current increase

- Drying of electrolyte (aluminum capacitors)

- Short circuit (tantalum under overstress)

- Open circuit

- ESR increase causing heating

- Explosion due to polarity reversal or overvoltage

- Thermal runaway (tantalum MnO₂ types)

Advantages of Polarized Capacitors

- Extremely high capacitance values

- Small size for capacitance rating

- Good DC filtering capability

- Available in high-voltage ratings (aluminum)

- Long-term stability (tantalum, niobium, polymer types)

- Essential for SMPS design

Disadvantages of Polarized Capacitors

- Polarity restrictions

- Cannot be used in AC signals

- Electrolyte drying (aluminum types)

- Limited high-frequency performance

- Risk of explosion if misused

- Tantalum cost is high

- Supercapacitors have limited voltage

Applications of Polarized Capacitors

- Power Electronics

- SMPS input/output filtering

- DC-Link capacitors

- Rectifier smoothing

- Motor driver filtering

- Consumer Electronics

- Smartphones

- TVs

- Audio systems

- Laptops

- Embedded & Digital Systems

- Decoupling microcontroller power rails

- Noise filtering

- Energy Storage

- Camera flash circuits

- Supercapacitor banks

- Memory backup

- Automotive & Industrial

- EV regenerative braking (supercapacitors)

- ECU filtering

- Motor control units

- Communication & Audio Circuits

- Coupling/decoupling audio signals

- RF power supply filtering

Conclusion

Polarized capacitors are indispensable components in electronics, especially when large capacitance, noise reduction, and energy storage are needed. Their construction varies significantly — ranging from aluminum foils wound with electrolytes to highly advanced tantalum and niobium oxide structures, and even to energy-packed supercapacitors.

Understanding their symbols, construction, working principle, advantages, disadvantages, and applications is crucial for designing reliable power supplies, audio circuits, embedded systems, and high-performance SMPS circuits.

Types of Capacitors with Symbol, Classification and Applications

Non-Polarized Capacitors – Symbol, Types, Construction, Working and Applications

What is Coupling Capacitor, Construction, Working & Applications

Difference Between Coupling, Decoupling, and Bypass Capacitors

Ceramic vs Electrolytic Capacitor: Key Differences and Applications