Solar energy has emerged as one of the most viable and sustainable energy sources in recent years. As the world grapples with the consequences of climate change and seeks to reduce its reliance on fossil fuels, solar panels have become a critical component of the global energy transition. This comprehensive guide explores the different types of solar panels, their applications, advantages, and disadvantages, providing a thorough understanding of this essential technology.

Basics Working of Solar Panels:

Solar cells convert sunlight into electricity using the photovoltaic effect. They consist of photovoltaic (PV) cells made from semiconductor materials like silicon. When sunlight strikes these cells, it excites electrons, creating electron-hole pairs. An electric field at the junction between the positively doped (p-type) and negatively doped (n-type) layers of the semiconductor separates these charges, generating a flow of electrons. This flow creates direct current (DC) electricity, which is then converted to alternating current (AC) by an inverter for use in homes and businesses. Factors such as material quality, temperature, and positioning affect the efficiency of this energy conversion process.

Types of Solar Panels:

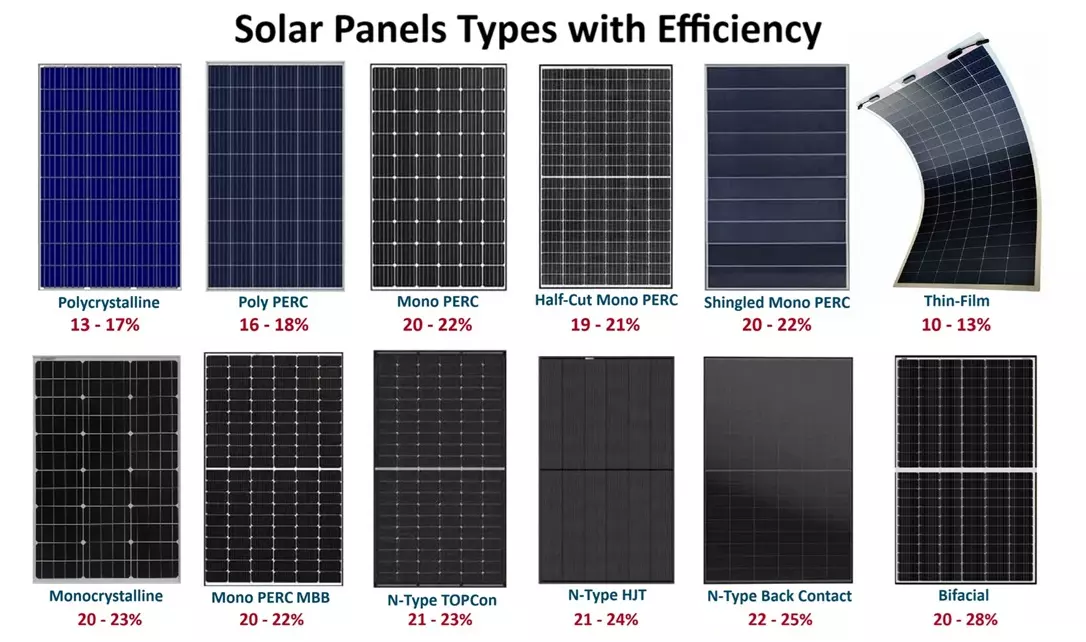

There are three main types of solar panels commonly used today: monocrystalline, polycrystalline, and thin film. Each type has its unique characteristics, making them suitable for different applications and environments.

1. Monocrystalline Solar Panels:

Description:

Monocrystalline solar panels are made from a single continuous crystal structure. They are easily recognizable by their uniform dark color and rounded edges.

Manufacturing Process:

The production of monocrystalline panels involves the Czochralski method, where a single crystal seed is placed in molten silicon. The seed is then slowly pulled upwards, allowing the crystal to form around it. Once the crystal is formed, it is sliced into thin wafers to create the solar cells.

Advantages:

- High Efficiency: Monocrystalline panels have the highest efficiency rates, typically ranging from 15% to 22%. This means they can produce more electricity from the same amount of sunlight compared to other types.

- Longevity: These panels tend to have longer lifespans, often backed by warranties of 25 years or more.

- Space-Efficient: Due to their higher efficiency, fewer panels are required to achieve the same power output, making them ideal for smaller spaces.

Disadvantages:

- Cost: They are generally more expensive to produce, and purchase compared to other types.

- Performance in Shade: Their performance can significantly drop if part of the panel is shaded.

Applications:

Monocrystalline panels are best suited for residential and commercial installations where space is limited, and high efficiency is paramount.

2. Polycrystalline Solar Panels:

Description:

Polycrystalline solar panels are made from silicon crystals that are melted together. They are characterized by their blue color and speckled appearance.

Manufacturing Process:

The silicon used in polycrystalline panels is melted and poured into a square mold, then cooled and cut into square wafers. This process is simpler and less expensive than the one used for monocrystalline panels.

Advantages:

- Cost-Effective: They are less expensive to manufacture and purchase than monocrystalline panels.

- Efficiency: While they are less efficient than monocrystalline panels, they still offer good performance, typically ranging from 13% to 18%.

- Durability: Polycrystalline panels are durable and have a lifespan comparable to monocrystalline panels.

Disadvantages:

- Lower Efficiency: They are less efficient than monocrystalline panels, requiring more space to generate the same amount of electricity.

- Heat Sensitivity: Their performance can decrease at higher temperatures.

Applications:

Polycrystalline panels are suitable for larger installations where space is not a constraint, such as solar farms and large commercial rooftops.

3. Thin-Film Solar Panels:

Description:

Thin-film solar panels are made by depositing one or more thin layers of photovoltaic material onto a substrate. They can be made from a variety of materials, including cadmium telluride (CdTe), amorphous silicon (a-Si), and copper indium gallium selenide (CIGS).

Manufacturing Process:

The process involves depositing the photovoltaic material onto a substrate such as glass, plastic, or metal. This method allows for flexibility in the design and application of the panels.

Advantages:

- Versatility: Thin-film panels can be made flexible, allowing them to be used in a variety of applications, including curved surfaces and portable solar devices.

- Cost: They are generally less expensive to produce than crystalline-based panels.

- Performance in Shade: Thin-film panels tend to perform better in low-light conditions and are less affected by shading.

Disadvantages:

- Efficiency: They have lower efficiency rates, typically ranging from 10% to 12% max up to 18%, which means more panels are needed to generate the same amount of electricity.

- Space Requirement: Due to their lower efficiency, they require more space for installation.

Applications:

Thin-film panels are ideal for applications where flexibility is needed, such as on building-integrated photovoltaics (BIPV), vehicles, and portable devices.

Emerging Solar Panel Technologies:

In addition to the three main types of solar panels, there are several emerging technologies that promise to enhance the efficiency and versatility of solar energy.

1. Bifacial Solar Panels:

Description:

Bifacial panels are better than other types of solar panels, capturing sunlight on both sides and increasing their energy output. They can be either monocrystalline or polycrystalline and are typically installed on reflective surfaces to maximize their efficiency. They can be combined with other technologies like HJT, PERC, half cut etc.

Manufacturing Process:

The manufacturing of bifacial solar panels involves preparing high-quality silicon wafers, followed by the application of anti-reflective coatings on both sides to maximize light absorption. Metal contacts are formed on both the front and back surfaces to capture electricity from sunlight hitting both sides. The cells are then assembled into panels with transparent backing materials, allowing sunlight to pass through and be absorbed from the rear side as well, enhancing overall energy generation. The final step includes encapsulation, framing, and adding a junction box for electrical connections.

Advantages:

- Increased Energy Yield: By capturing sunlight from both sides, bifacial panels can generate more electricity than traditional single-sided panels.

- Durability: They are often more durable, as they are designed to withstand environmental stressors on both sides.

Applications:

Bifacial panels are ideal for installations with reflective surfaces, such as white rooftops, ground-mounted systems with reflective ground covers, and areas with high albedo (reflectivity).

2. PERC (Passivated Emitter and Rear Cell) Panels:

Description:

PERC panels are an advancement in monocrystalline technology. They include an additional layer on the back of the cell to capture more sunlight and convert it into electricity.

Manufacturing Process:

The manufacturing of PERC panels involves several key steps. First, high-quality p-type crystalline silicon wafers are prepared. The front side of the wafer is then doped to create a p-n junction, forming the emitter. A thin passivation layer, typically silicon nitride, is applied to the front to reduce surface recombination. On the rear side, an additional passivation layer, often aluminum oxide, is deposited, followed by a reflective coating that enhances light absorption. Metal contacts are added to the front and rear surfaces for electrical collection, and the cells are finally assembled into panels. This process improves efficiency by increasing light capture and reducing electron recombination.

Advantages:

- Higher Efficiency: The additional layer helps to increase the efficiency of the panels, often by a few percentage points.

- Improved Performance in Low Light: PERC panels perform better in low-light conditions and at higher temperatures.

Applications:

PERC panels are suitable for residential and commercial installations where high efficiency and performance are required.

3. Heterojunction (HJT) Solar Panels:

Description:

HJT panels combine two types of silicon—amorphous and crystalline—to create a highly efficient solar cell.

Manufacturing Process:

The manufacturing of Heterojunction (HJT) solar panels involves preparing high-quality N-type crystalline silicon wafers, followed by depositing thin layers of amorphous silicon on both sides using PECVD to create junctions. A Transparent Conductive Oxide (TCO) layer is then added to conduct electricity while allowing light to reach the silicon. Metal contacts are formed on the front and back to collect electricity, and finally, the HJT cells are assembled into panels through encapsulation, framing, and adding a junction box, resulting in high-efficiency solar panels.

Advantages:

- High Efficiency: HJT panels offer some of the highest efficiency rates available, often exceeding 20%.

- Longevity: They have long lifespans and are resistant to light-induced degradation.

Applications:

HJT panels are ideal for applications where maximum efficiency is critical, such as space-constrained residential and commercial installations.

4. TOPCON (Tunnel Oxide Passivated Contact) Solar Panels:

Description:

Topcon solar panels represent a significant advancement in solar cell technology. They use a Tunnel Oxide Passivated Contact structure to improve efficiency and performance.

Manufacturing Process:

The Topcon technology involves adding an ultra-thin oxide layer and a polysilicon layer to the back surface of the solar cell. This creates a passivated contact that reduces recombination losses, which occur when electrons and holes recombine before they can be collected as electrical current.

Advantages:

- High Efficiency: Topcon cells can achieve higher efficiencies, often exceeding 23%, due to reduced recombination losses.

- Improved Performance: These panels perform well in various environmental conditions, including high temperatures and low light.

- Longevity: The passivated contact improves the durability and longevity of the cells.

Applications: Topcon panels are suitable for both residential and commercial installations where high efficiency and long-term performance are crucial.

5. Shingled Solar Panels:

Description:

Shingled solar panels use a unique design where solar cells are cut into strips and overlaid in a shingled pattern, similar to roof shingles. This design eliminates the gaps between cells, maximizing the active area and enhancing the panel’s efficiency.

Manufacturing Process:

The solar cells are cut into narrow strips and then connected using conductive adhesives. These strips are overlapped slightly, creating a continuous surface that reduces resistance and increases power output.

Advantages:

- Higher Efficiency: By eliminating the gaps between cells, shingled panels increase the active area, resulting in higher efficiency.

- Enhanced Aesthetics: The shingled design provides a sleek, uniform appearance, making these panels visually appealing for residential installations.

- Improved Durability: The overlapping cells distribute stress more evenly, reducing the risk of microcracks.

Applications:

Shingled panels are ideal for residential and commercial rooftops where both aesthetics and performance are important.

6. MBB (Multi-Busbar) Solar Panels:

Description:

MBB technology involves using multiple thin busbars to collect and transport the electrical current generated by the solar cells. Traditional solar panels typically use 3 to 5 busbars, while MBB panels can use up to 12 or more.

Manufacturing Process:

The solar cells are printed with multiple thin busbars instead of the conventional wider busbars. This design reduces the distance that electrons must travel, thereby decreasing resistance and improving efficiency.

Advantages:

- Higher Efficiency: The multiple busbars reduce resistance losses and improve the overall efficiency of the panels.

- Enhanced Durability: The distributed current collection reduces the risk of microcracks and other defects.

- Improved Performance: MBB panels perform better under partial shading and low-light conditions.

Applications:

MBB panels are suitable for residential, commercial, and utility-scale installations where high efficiency and reliability are important.

7. Back Contact Solar Panels:

Description:

Back Contact solar panels use N-type silicon cells, which have a higher efficiency and better temperature coefficient than the more common P-type cells. These panels also have all electrical contacts on the back of the cell, which reduces shading on the front surface.

Manufacturing Process:

N-Type cells are doped with phosphorus, creating an abundance of free electrons. The back contact design involves placing all the electrical contacts on the rear of the cell, allowing for a cleaner front surface that can capture more sunlight.

Advantages:

- High Efficiency: N-type cells have higher efficiencies and better performance in high temperatures compared to P-type cells.

- Improved Aesthetics: The back contact design provides a sleek, uniform appearance with no visible busbars on the front.

- Longevity: N-type cells are less prone to light-induced degradation and have longer lifespans.

Applications:

N-Type Back Contact panels are ideal for high-efficiency residential and commercial installations where aesthetics and performance are paramount.

8. Half-Cut Solar Panels:

Description:

Half-Cut solar panels use cells that are cut in half, which reduces resistance and improves efficiency. This design also enhances the panel’s performance under shading and partial shading conditions.

Manufacturing Process:

The traditional solar cells are cut into halves, and these half-cells are wired together in a way that reduces resistance and improves overall efficiency. The design typically involves more busbars to further enhance performance.

Advantages:

- Higher Efficiency: By reducing the current in each cell, half-cut cells experience lower resistive losses, increasing efficiency.

- Better Shade Tolerance: The wiring design improves the panel’s performance under shading and partial shading conditions.

- Enhanced Durability: The reduced stress on each cell helps prevent microcracks and other defects.

Applications:

Half-Cut panels are suitable for residential, commercial, and utility-scale installations, particularly in areas prone to shading or partial shading.

Factors to Consider When Choosing Solar Panels:

When selecting solar panels for a specific application, several factors should be considered:

- Efficiency: Higher efficiency panels generate more electricity in the same amount of space, making them ideal for areas with limited installation space.

- Cost: Budget constraints may influence the choice of panel type. While monocrystalline panels are more efficient, polycrystalline and thin-film panels are more cost-effective.

- Durability: The expected lifespan and warranty of the panels should be taken into account. Monocrystalline panels often have longer warranties, but all panel types can be durable if properly maintained.

- Climate and Location: The local climate and amount of sunlight available can impact the performance of different panel types. For example, thin-film panels may perform better in cloudy or shaded environments.

- Space Availability: The amount of available space for installation will influence the choice of panel type. High-efficiency panels like monocrystalline are ideal for small spaces, while thin-film panels can be used in larger areas or unique applications.

Conclusion:

Solar panels have become a cornerstone of the renewable energy landscape, offering a sustainable and increasingly cost-effective solution for electricity generation. By understanding the different types of solar panels — monocrystalline, polycrystalline, and thin-film, along with emerging technologies like — bifacial, PERC, Topcon, Shingled, Multi-Busbar, N-Type Back Contact, Half-Cut and HJT panels, individuals and businesses can make informed decisions about the best solar solutions for their needs.

As technology continues to advance, the efficiency, affordability, and versatility of different types of solar panels will only improve, further solidifying their role in the global transition to clean energy. Whether for residential, commercial, or industrial applications, solar panels offer a powerful tool in the fight against climate change and the quest for a sustainable future.

good one. really grateful.