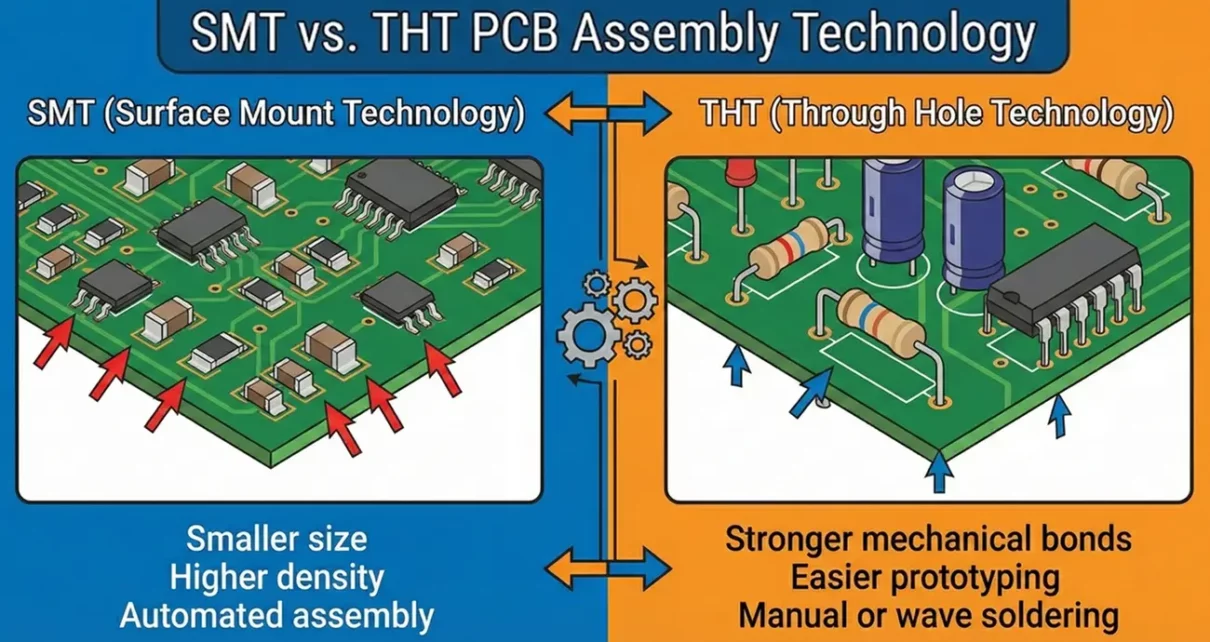

Printed Circuit Board (PCB) assembly is the heart of modern electronic product manufacturing. Two primary methodologies dominate PCB assembly: Surface Mount Technology (SMT) and Through-Hole Technology (THT). Each technology has unique characteristics, advantages, limitations, and ideal use cases.

This article presents a detailed, side-by-side examination of SMT and THT, covering fundamentals, process steps, component types, manufacturing considerations, testing, reliability, cost implications, and application domains.

1. Definitions and Basic Concepts

1.1 Surface Mount Technology (SMT)

SMT refers to the method of mounting electronic components directly onto the surface of a PCB. Components have leads or terminations designed to be soldered to surface pads rather than inserted into drilled holes.

Surface Mount Devices (SMDs) are typically small, often rectangular, and have flattened leads or contacts on the sides or bottom.

1.2 Through-Hole Technology (THT)

THT involves inserting component leads through pre-drilled holes in the PCB and then soldering them on the opposite side. This mechanical anchoring method preceded SMT and was the dominant assembly technique for decades.

Components used in THT are typically larger and have leaded packaging to facilitate placement through the board.

2. Component Types and Packages

2.1 SMT Components

Common SMT packages include:

- Resistors/Capacitors: 0201, 0402, 0603, 0805, 1206, etc.

- Integrated Circuits: QFP, TQFP, QFN, BGA, SOIC.

- Inductors/Transformers: Flat inductors with surface pads.

- Connectors: Surface mount headers and board-to-board connectors.

Characteristics:

- Leadless and low-profile.

- Optimized for automated pick-and-place.

- Minimal board space usage.

2.2 THT Components

Typical through-hole components include:

- Axial/ Radial Resistors and Capacitors

- Electrolytic Capacitors

- Large ICs on DIP packages

- Power Components: Transformers, large inductors.

- Connectors and Switches

Characteristics:

- Leads pass through PCB holes.

- Often larger footprint and higher profile.

- Strong mechanical retention.

3. Assembly Processes

3.1 SMT Assembly Workflow

The SMT process generally follows these steps:

- Solder Paste Application: A stencil is used to apply solder paste to surface pads.

- Pick-and-Place: Automated machines place SMDs accurately on solder paste.

- Reflow Soldering: The board passes through a reflow oven, melting solder paste to form joints.

- Inspection: Optical and X-ray inspection ensures quality.

3.2 THT Assembly Workflow

THT assembly includes:

- Component Insertion: Manual or automated insertion of leaded components.

- Wave Soldering / Selective Soldering: Boards are soldered via wave solder machines or selective tips.

- Lead Trimming / Cleaning: Excess lead is removed and PCB is cleaned.

- Inspection: Visual and electrical testing.

3.3 Mixed Assembly

Many modern PCBs combine SMT and THT (mixed technology). SMT components populate one side while select THT parts may populate the other. This harmonizes benefits of both technologies.

4. Advantages and Disadvantages

4.1 SMT Advantages

- Miniaturization: Enables compact designs and higher component densities.

- Automated Manufacturing: High throughput, precise placement, and repeatability.

- Cost-Effective in Volume: Lower part costs and efficient assembly scale.

- Electrical Performance: Shorter leads reduce parasitic inductance/capacitance – valuable at high frequencies.

- Double-Sided Assembly: Both PCB sides can be populated.

4.2 SMT Disadvantages

- Mechanical Strength: Lower mechanical robustness compared to THT for heavy components.

- Repair Complexity: Small size complicates manual rework and inspection.

- Thermal Stress: Reflow processes can stress sensitive components.

4.3 THT Advantages

- Mechanical Strength: Through-hole solder joints provide durable mechanical retention – ideal for connectors, heavy components, or high-stress environments.

- Ease of Prototyping: Simpler for manual assembly during prototyping.

- High Power Components: Better suited for high power, high heat dissipation parts.

4.4 THT Disadvantages

- Board Space Utilization: Requires larger PCBs with greater hole drilling and spacing.

- Slower Assembly: Manual or semi-automated insertion increases production time and labor costs.

- Higher Cost at Scale: More material and labor increases unit cost.

5. Manufacturing Considerations

5.1 PCB Design and Fabrication

- SMT: Smaller pads and finer pitch require precise fabrication; track/space constraints demand advanced photolithography.

- THT: Drilled holes add to fabrication time and board cost; hole plating and annular ring control are critical.

5.2 Equipment Investment

- SMT: Capital expenditure on pick-and-place machines, reflow ovens, solder paste inspection (SPI), and AOI.

- THT: Wave solder machines and selective soldering platforms; however, assembly is more labor-intensive.

5.3 Component Sourcing and Inventory

SMT components are compact and abundant in modern supply chains, whereas some THT parts remain common for legacy or power applications.

6. Inspection and Testing

6.1 Inspection Challenges

- SMT: Smaller joints require optical inspection and often X-ray for BGAs.

- THT: Visual inspection is more straightforward but hidden joints under components need attention.

6.2 Testing Approaches

- In-Circuit Testing (ICT): Used across both technologies for continuity and functional checks.

- Automated Optical Inspection (AOI): Highly effective for SMT.

- X-ray Inspection: Necessary for complex SMT components with hidden solder joints.

7. Reliability and Performance

7.1 Electrical Performance

SMT generally offers superior high-frequency performance due to shorter electrical paths and lower parasitics. THT can introduce additional inductance/capacitance due to lead lengths.

7.2 Mechanical Reliability

THT excels in mechanical endurance – especially for connectors or parts subject to vibration. SMT reliability has improved significantly with modern solder alloys and process controls but remains sensitive to mechanical shock without reinforcement.

8. Cost Analysis

8.1 Unit Cost

- SMT: Lower per unit cost at scale due to automation and miniaturization.

- THT: Higher costs due to labor and larger part footprints.

8.2 Tooling and Setup

SMT requires significant upfront equipment investment but amortizes over volume. THT may incur lower equipment costs but higher operational costs.

9. Applications and Industry Trends

Surface-Mount Technology (SMT) and Through-Hole Technology (THT) coexist in modern electronics manufacturing, with each serving distinct functional, mechanical, and economic roles. While SMT dominates high-volume and high-density applications, THT continues to be essential where mechanical strength, high current, or extreme reliability are required.

9.1 SMT Dominance

SMT is the default choice for most modern electronic products due to its compactness, automation compatibility, and electrical performance.

SMT is the preferred technology for:

- Mobile electronics

Smartphones, tablets, wearables, and laptops rely on SMT to achieve extremely high component density, thin form factors, and low parasitic losses at high frequencies. - Consumer gadgets

Televisions, gaming consoles, smart home devices, and appliances benefit from SMT’s low assembly cost, high production throughput, and minimal board real estate usage. - High-speed digital and RF electronics

SMT minimizes lead inductance and capacitance, improving signal integrity for high-frequency and high-speed interfaces such as DDR memory, PCIe, 5G RF modules, and microwave circuits. - Compact IoT devices

Battery-powered sensors, wireless modules, and embedded nodes use SMT for low power consumption, small size, and ease of integration into multi-layer PCBs.

Additional advantages driving SMT dominance include:

- Compatibility with fully automated pick-and-place and reflow processes

- Reduced material and shipping costs due to smaller and lighter assemblies

- Improved thermal performance through exposed pads and thermal vias

- Support for advanced packaging such as QFN, CSP, BGA, and SiP modules

As a result, SMT is effectively mandatory for any application requiring high volume, high density, or high speed.

9.2 THT Relevance

Despite SMT’s dominance, THT remains essential where mechanical strength, power handling, and long-term reliability are critical.

THT remains important for:

- Power electronics

Large capacitors, transformers, inductors, high-current connectors, and power semiconductors benefit from THT’s strong mechanical anchoring and higher current-carrying capability. - Industrial controls

PLCs, motor drives, and automation equipment often operate in harsh environments involving vibration, heat, dust, and humidity – conditions under which THT solder joints are more robust. - Aerospace and defense

Mission-critical systems prioritize reliability, shock resistance, and inspectability. THT allows easier visual inspection, rework, and verification, which are essential for safety-critical electronics. - Prototyping and educational development

THT components are easier to handle manually, easier to replace, and better suited for breadboarding and laboratory work.

Additional factors sustaining THT usage:

- Superior resistance to mechanical stress, vibration, and connector insertion forces

- Better suitability for very high voltages and high currents

- Easier rework and repair in field environments

- Compliance with legacy designs and long product life cycles

Thus, THT remains indispensable in high-power, high-reliability, and low-volume specialized systems.

9.3 Emerging Trends

Modern electronics design increasingly blends SMT and THT to optimize performance, cost, and reliability.

Key emerging trends include:

- Selective application and mixed technology

Designers increasingly use hybrid PCBs, combining SMT for signal processing and control logic with THT for power, connectors, and mechanically stressed components. - Miniaturization pressures

SMT continues to push packaging limits with ultra-small passive components (01005 and below), micro-BGAs, wafer-level chip-scale packages (WLCSP), and embedded components. - Advanced PCBs and HDI adoption

High-Density Interconnect (HDI) PCBs use microvias, fine-line traces, and sequential lamination to support SMT’s density and routing demands in smartphones, medical devices, and automotive electronics. - Thermal and power integration

New SMT power packages (e.g., power QFNs, bottom-cooled BGAs, and integrated modules) are narrowing the gap between SMT and THT for high-power applications. - Automation and Industry 4.0

Smart factories integrate real-time inspection (AOI, AXI), traceability, and closed-loop process control to improve SMT yield, reduce defects, and enable predictive maintenance. - Reliability engineering emphasis

Simulation-driven design, accelerated life testing, and advanced solder alloys are improving SMT reliability in automotive, medical, and industrial sectors.

10. Comparison of SMT and THT

| Criterion | SMT | THT |

|---|---|---|

| Component Size | Very small | Larger |

| Board Density | High | Lower |

| Assembly Speed | Fast | Slower |

| Mechanical Strength | Moderate | High |

| Automation | Highly automated | Less automated |

| Cost (High Volume) | Lower | Higher |

| Prototyping | Challenging | Easier |

| High Power Handling | Limited | Better |

| Inspection Difficulty | Higher | Lower |

Conclusion

Both SMT and THT have distinct strengths that make them appropriate for different applications. SMT has become the backbone of modern PCB assembly due to miniaturization, automation, and electrical performance advantages. Conversely, THT retains relevance where mechanical strength and ease of assembly are priorities.

In contemporary manufacturing, mixed technology designs leverage the best of both worlds: SMT for small, high-density components, and THT for connectors, high-stress, or power components.

A thorough understanding of both assembly technologies enables PCB designers and manufacturing engineers to optimize reliability, performance, manufacturability, and cost.

Revolutionary Axial Flux Printed Circuit Board (PCB) Stator Motor

High Speed PCB Design: Essential Wiring Techniques for Optimal Performance

What is Electronic Assembly & Work with EMS PCBA Manufacturer